Edit Content

Manufacturing Process of Gabion Baskets

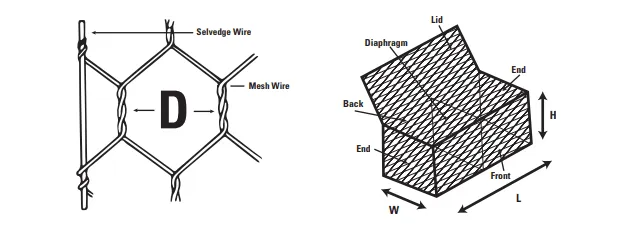

High-quality low-carbon steel wire is fed into a weaving machine. The machine utilizes a double-twisted hexagonal weaving technique to automatically twist multiple wires together, forming a sturdy, hexagonal honeycomb mesh structure. This double-twisting method prevents unravelling and provides exceptional structural integrity.

The large rolls of woven mesh are then cut into individual panels according to specific order requirements. These panels are bundled for shipment. To optimize space, the panels are typically compressed and bundled flat.

A complete, ready-to-assemble gabion unit generally includes the following components: a base panel, lid panel, end panels (front and rear), side panels (left and right), and any necessary internal diaphragm panels.